Manufacturing Project Management Software for SOP, Quality and Compliance

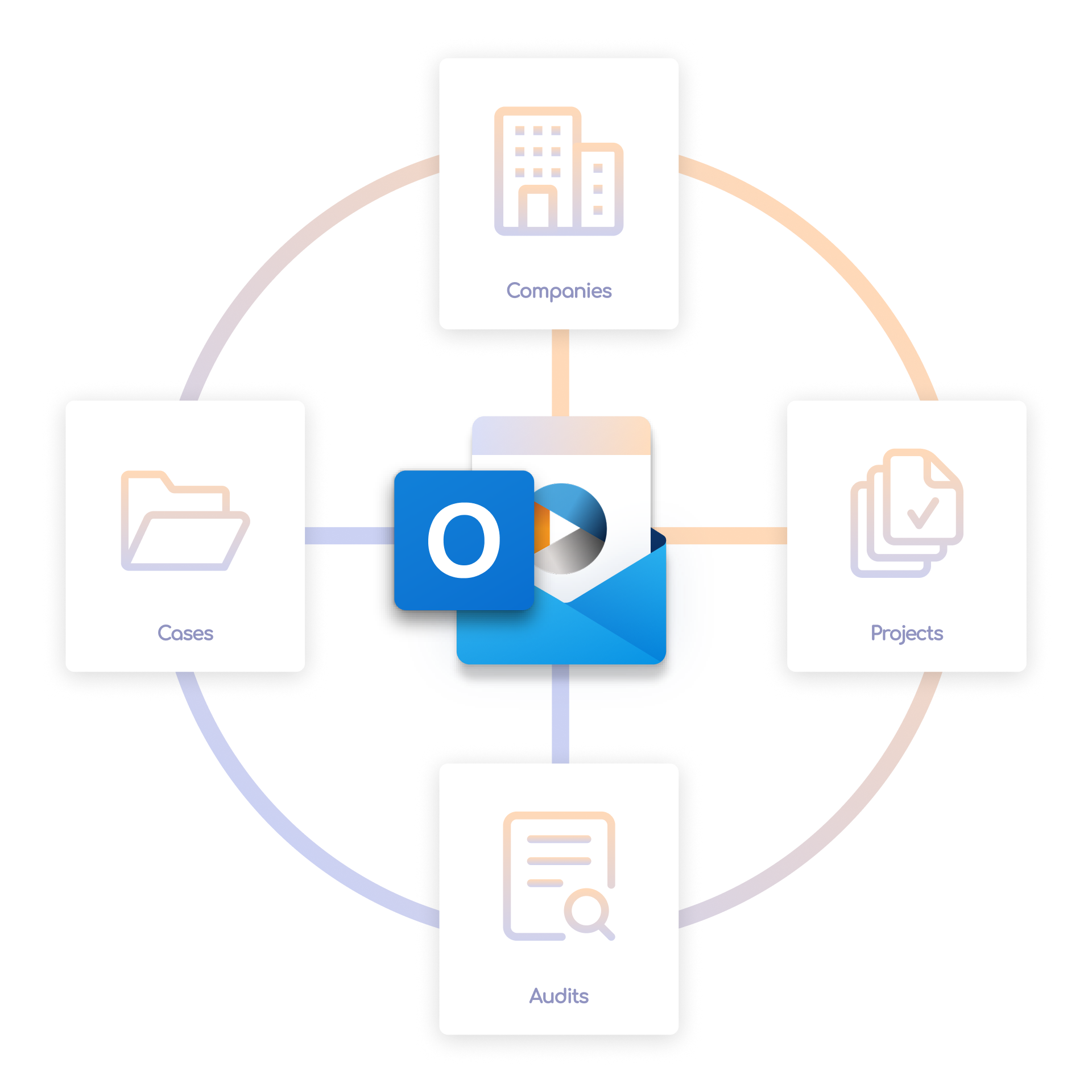

Production delays, compliance risks and knowledge gaps cost time and money. WorkPoint 365 connects teams, documents and workflows in Microsoft 365, helping manufacturers improve efficiency, reduce errors and stay audit-ready.

Centralized CAPA and SOP Management for Manufacturing in Microsoft 365

Disconnected SOPs, scattered deviation reports and siloed audit files make it hard to maintain quality and momentum on the production floor. Teams waste time chasing information, while compliance risks quietly grow.

WorkPoint 365 solves this by centralising work instructions, automating CAPA workflows and giving QA, production and maintenance a shared, real-time view in Microsoft 365 - reducing errors, speeding up responses and keeping inspectors satisfied.

3 Key Benefits of WorkPoint 365 for Manufacturing Companies

Standardise SOPs & Work Instructions

With WorkPoint 365, you get a centralized SOP management system that ensures every version is controlled, accessible, and audit ready. No one will be working from the wrong file. Step-by-step processes such as work instructions, automated notifications, and read-and-sign logs make it easy to track who has seen what while the training evidence is automatically recorded.

Automate Deviations, NCR & CAPA Workflows

WorkPoint 365 takes the manual work out of deviation management. Non-conformances are routed to the right stakeholders automatically, with built-in approvals, automated notifications, and clear deadlines for tracked actions. CAPAs are tracked from start to finish, with full visibility for QA processes and production.

ERP & MES Integration – No Double Data Entry

WorkPoint 365 integrates easily with your existing ERP and MES systems, such as Microsoft Dynamics, SAP, or your shop floor MES. That means order and lot data, and production info flow directly into your quality and document workflows, eliminating manual entry and reducing errors. No more copy-pasting, no more mismatches.

Increasing Efficiency in a Changing Workforce

Manufacturing is facing a growing skills gap. As experienced workers retire and fewer new entrants join the industry, critical knowledge is at risk of being lost. While automation and robotics continue to evolve, human insight remains essential. WorkPoint 365 helps bridge this gap by standardising processes, centralising documents, and making knowledge instantly accessible through connected Microsoft 365 and SharePoint tools. Now your teams get faster access to the information they need, enhacing efficiency and keeping production moving.

Compliance made easy

Manual processes and logging of events leave too much room for error and is the fastest route to non-compliance and audit troubles. As a key part in all our solutions, WorkPoint Automate enables you to put your audit trail, log and e-signature notifications on autopilot with document management software tailored to manufacturing companies.

Ensure manufacturing compliance and stay audit-ready for things such as ISO 9001 certifications and more.

Real-time dashboards with Power BI

A smooth-running production floor requires real-time overview of key production and quality KPIs. WorkPoint 365 is not just a central hub for all your documents and automated processes; it has almost endless possibilities for integrations to other key systems as well, systems such as your ERP/MES, Power BI and more, making it your dedicated production project management software pulling on multiple sources for live information.

Whether you want to check your OEE or scrap rate metrics, WorkPoint 365 is your key integrator with the power to show you all that you need in a tailored quality dashboard via Power BI.

What our Customers are Saying...

What I was most impressed by with WorkPoint, is just how easy it is to build the system around it. How the architecture is built, and how scalable and flexible the system it.

Get in touch